My career started at the age of 19 along with my college friend Anthony Arthur Cox by signing on to the organisation known as the Atomic Energy Research Establishment, Harwell in Berkshire on the 4th of September 1961. The new intake of Scientific Assistants were accommodated firstly in Fellow Close, Abingdon by the river for a time then to shared rooms in B-Mess on site. I was given three months in the training centre run by a Mr JG Robbins with a Mr Don Warren as trainer on the Chemistry side. In January 1962 I was transferred to the Chemical Engineering division run by Mr White.

After Christmas 1961 I joined a team in the active laboratory of Building 353 working on a research programme called FINGAL (Fixation IN Glass of Active Liquors) as a Scientific Assistant under the management of Dr John R Grover and Mr Malcolm Elliot. The team was composed of Messers Gaylor, Jordan, Walmsley, Auty, Sammons, Orm and myself plus two process workers Messers Hughes and White.

The FINGAL process was designed to take the spent liquid fuel rod waste from power stations and (together with a liquid mix of silica and borax) pumped as two streams into a 6 foot stainless steel cylinder which was heated to a temperature of over 1000 degrees C. The mixture (with time) would slowly become a homogenous glass mix which included the waste isotopes. My understanding was that these highly radioactive cylinders would be cooled to room temperature and then safely stored underground for many years until the isotopes with long half lives had degenerated to acceptable levels. The process included research into why the metallic form of the rare earth Ruthenium plated out on the inside of the off-gas tubes causing blockages to occur. The final room temperature product had its internal glass structure analysed by exposing the cylinder to a Cobalt-60 source with a photographic plate on the other side and an overnight exposure when building 353 was empty of staff. This gave an image of the glass structure inside the cylinder and just how well (ie. homogeneous) the glass structure had become.

I also had a short spell working for Professor Mark de Chazal from Mauritius who was at Harwell for one year with Dr Grover conducting research into desalination. This involved making a thin gel which, when trapped between two stainless steel plates, would only allow pure water to pass through the gel when pressure was applied to one side of the plate using foul water against the membrane.

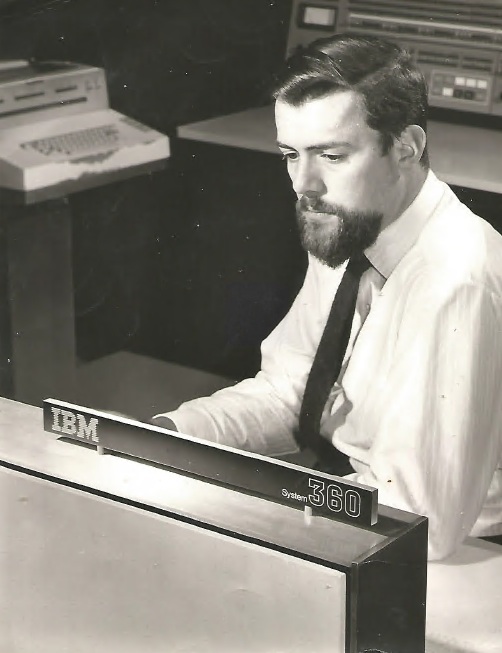

My work on the FINGAL process under Mr Elliot involved creating samples of silica borax glass containing radioactive isotopes of caesium, cerium, strontium and uranium. These samples were then crushed and a certain size fraction sifted out and placed into polythene tubes which were positioned in a rig which was constructed to hold several tubes. Each tube had a specific quantity of deionised water passed over each internal active sample by a rotating arm for a certain length of time. The objective was to investigate the quantity of each radioactive isotope which had been leached out. Some experimental rigs had the water spiked with different inactive salts to see if there was any reduction to the quantity of isotope leached out from each test sample. The samples were counted for evidence of radioactivity using a 100 channel analyser with its sensor located inside a thick lead castle to reduce the effect of any external natural radiation giving incorrect readings. The results were punched out on 80 column cards (10 cards to each sample). These cards were converted daily onsite from punched card to magnetic tape using an IBM 360/30 computer and then processed nightly on the IBM computer at AWRE Aldermaston using a program generated by Dr David Salmon of Chemistry Division.

Next to our active laboratory was a different experimental research programme looking into carbon fibre production under the watchful eye of Mr Brian Longstaff. I can remember going to a presentation of the research by the then Director of Harwell, Dr Walter Marshall in the Cockcroft Lecture Hall where a piece of carbon fibre material rang like a bell when struck and was described as being at least as strong as steel.

In 1967 I moved to different job still as a Scientific Assistant in the new computer section of Theoretical Physics Division under Mr Alan Curtis learning how to run the onsite IBM 360/30 computer which had replaced the old valve Mercury computer. It was used to convert punched card data and programmes onto magnetic tape to be run on the Aldermaston 7030 computer overnight. The results were then printed out and next day back on site. In 1967 the whole new computer organisation moved from a terrapin hut to a newly built computer suite in building 8.12 and saw the installation of a large mainframe computer named IBM 360/65 which had 512k of main core store and one megabyte of Large Core Store (LCS). Input was by 80 column punched cards for the user's program and data input. The hardware consisted of several magnetic tape units and interchangeable disk storage devices as well as a drum storage unit. The disc units were composed of several magnetic plates in a stack with read-write heads recording and writing customer data in concentric circles and called files. Each stack had a directory of the unique location of each file and was called a Volume Table Of Contents (VTOC). The main software running the computer was called Disk Operating Software (DOS) which was stored on a disk unit and was accessed at start up time known as IPL Initial Program Load. Also requiring operation was a DEC PDP8 computer used to convert paper tape to magnetic tape for processing on the 360 which was later changed to a PDP10. The 360 was also used to develop the Harwell Users Workshop (HUW) which was an early form of an online system. This allowed on-site scientists to use a teletype in their laboratory or office and remotely access the 360 to process jobs. The hardware was organised with IBM engineer George Thompson and manager Len Landimore and the software by Chris Hatton.

The 360/65 main software was first run under Primary Control Program (PCP) which allowed just one job at a time to be read in, processed and printed out. As the IBM software advanced, the computer was upgraded to Multiprogramming with Fixed Task boundaries (MFT) whereby the central processing unit (CPU) allowed the processing of more than one job at any one time. This was complemented with software called Houston Automatic Spooling Program (HASP) which permitted several jobs to be read in and queued internally until sufficient space in the CPU was free to run waiting jobs depending how much core memory each job required. The overall software was able to decide which jobs to run concurrently. This software progressed into Multiprogramming with Variable Task boundaries (MVT) which increased the speed of processing jobs. The customer's punched card programs, subroutines and data were surrounded by control cards which specified instructions on the required behaviour of the user's job call Job Control Language (JCL). The user's program was written in either Fortran or Cobol whose instructions were checked by an internal compiler and if correct these instructions were converted into machine code (Assembler language). If incorrect the user had returned a diagnostic list or the errors.

In December 1970 I terminated the Harwell post and accepted a position as group leader on shift to run the main IBM and Univac computer floors of a major oil company in London. This produced a threefold salary increase and also a severe culture shock by moving from a government environment to a commercial one. However this proved a career progression as in January 1974 I was assigned the post of computer operations manager to oversee the updating of computer and data input systems for a petroleum development company in the Gulf, after which in the early eighties the same company made me training manager in London with a mandate to spread the word about these new portable computers (IBM) appearing on peoples' desks.

Second draft from Tony, 27 September 2025.